Project Name

Zero3 Low Temperature Bodies

Project Codenumber

UnAssigned

Notes

The way to achieve high fired strength at low temperatures has long been known: frit additions. But frit is far more expensive than typical body materials and low-fire did not seem a logical place to make stoneware when it comes so natural at cone 6 and 10. But imagine making ware of superior strength and density only a cone or two above your usual bisque temperature! And there are no sacrifices in workability, these bodies are highly plastic. The underglazes paint on very well.

Why was cone 03 chosen? Because 04 is too low and 02 is too high. Almost any low fire underglaze, glaze or overglaze will still work at cone 03. Also it is low enough to still develop good terra cotta red color and bubble free glazes but high enough that minimal frit is needed to densify it.

March 2022: We are working on a much whiter version of the engobe, L3685Z2. And two other glaze recipes, G1916Q and G3879. And moving this down to cone 04 (aka Zero4).

URLs

Zero3 Ulexite Transparent Glaze

For use with the Zero3 body and engobe

|

Code # G2931F |

| Materials | Amt |

|---|---|

| EPK | 27.000 |

| Silica | 7.000 |

| Ulexite | 29.000 |

| Ferro Frit 3249 | 9.000 |

| Wollastonite | 9.000 |

| Ferro Frit 3110 | 19.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.8:1 7.4 (Molar:7.5) 14.3 Cost 0.31 per kg |

Notes

This recipe converts the popular Worthington Clear Gerstley-Borate-based recipe into something much easier to use. While Worthington melts to a good clear it has serious gelling problems (characteristic of Gerstley Borate). Normal frits cannot easily source this high level of B2O3 so I have employed Ulexite to augment (a mineral similar to GB yet gels only slightly). Another issue with Worthington is shivering and fracturing of ware when glazed only on the inside (its thermal expansion was too low). This recipe also raises thermal expansion (by adding Na2O), the result is a glaze that fits a much wider range of bodies. Worthington also has clouding issues, this yields a more crystal clear, defect free fired result.

While reading this page, note that I later found that it was better to use frits to source the boron (rather than Ulexite or Gerstley Borate). That recipe is G2931K, it has a higher and lower expansion version also. So view this recipe as simply on the path from Worthington Clear to ultimately the Frit-based transparent, G2931K.

Dipping ware in Zero3 Transparent is just so much easier than trying to paint on than commercial, slow drying clears. It produces a slurry with very nice suspension, drying and application properties. It naturally gels (at around 1.4 SG in our lab). It applies very well in an even layer to low or high porosity bisque (the gel makes it hang on without running or dripping). However the 1.4 specific gravity (which is lower than most stoneware glazes) means that it dries slower if bisque is dense.

As a clear overglaze to finish your decorated ware, this glaze has a number of advantages over commercial clear glazes:

-It is much less expensive so it is practical to have a large pail of it so that pieces can be easily dip-glazed (using dipping tongs).

-It behaves like stoneware glazes, it suspends well and applies in an even layer that can dry to handling stage is seconds.

-It fires to a better crystal clear.

-Since the recipe is known, and contains no toxic materials, you can more confidently assure retailers that it is safe; all underglaze color decoration is isolated from any contact with food or drink by this glaze.

-It is compatible with most underglaze colors (including pinks).

Pay special attention to the soak-soak-slow cool firing schedule for this glaze, especially if your clay body is not fine grained.

Pictures

Terrastone, L215

The successful firing of these mugs represents two years of testing to learn how to get a crystal clear glaze and how to create slips that dry and fire bond well! The firing schedule is very important: Cone 03 soak-rise-soak-slowcool. Slips are bright colored (they contain only 10% stains).

Left: L3786E Plainsman Terrastone test mix with L3724M vitreous red slip with G2931F glaze. Wax resist exposes portions of the red slip which flashes near the glaze boundary.

Center: Terrastone with L3685U vitreous white slip inside and brushed on (and 10% stained versions of it brushed on) with G2931F glaze.

Right: L3724M vitreous red body with L3685U engobe (and stained versions of it) with G2931F glaze.

Shivers on L212

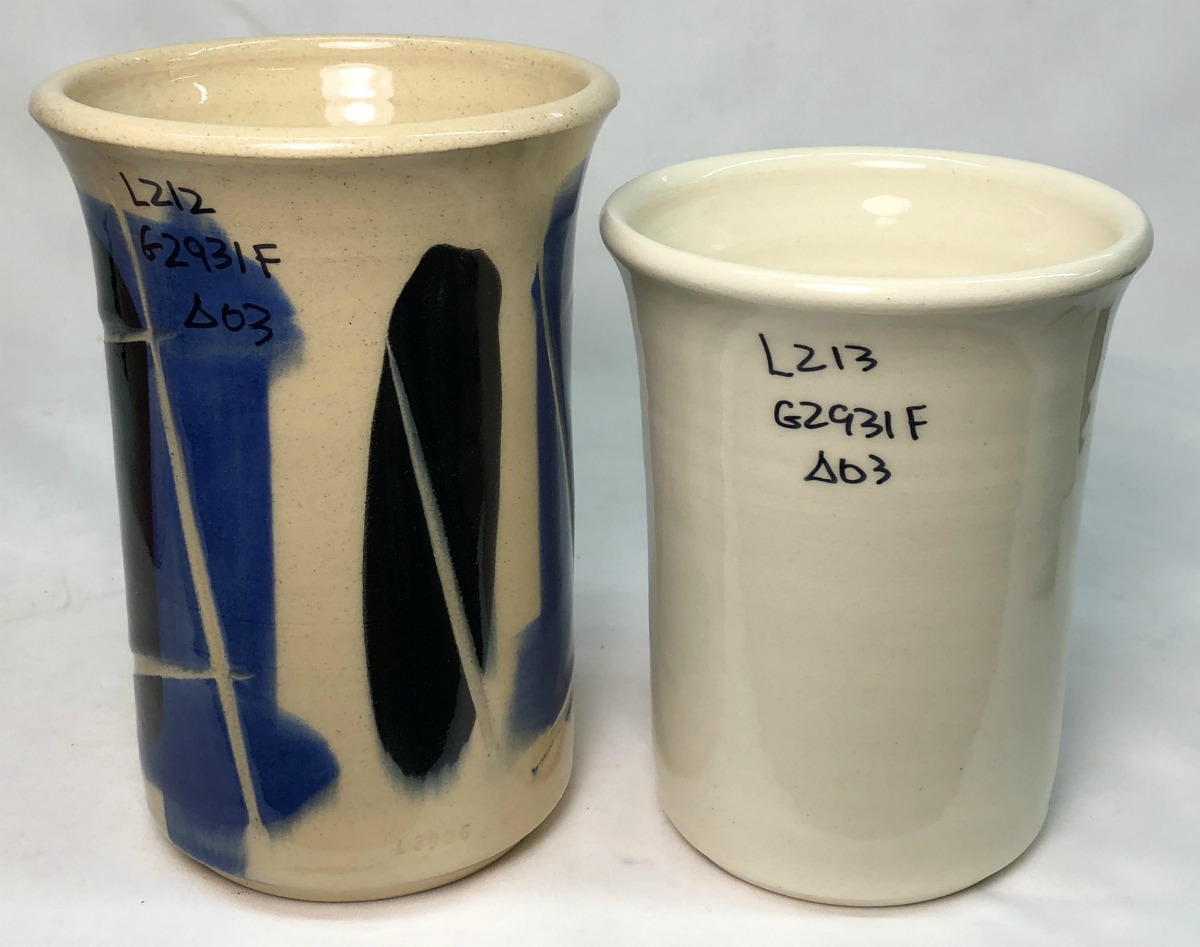

L213 with G2931F glaze cone 04, 03, 02

Boiling water, ice water tested. None crazed.

The cone 03 one was still good after a year.

Zero3 body with G2931F Zero3 glaze

The F version of the glaze employs Ulexite to source the boron (instead of frits). These Zero3 stoneware mugs were fired to cone 03 with underglazes. The right mug has the Zero3 engobe inside (under the glaze).

G2931F (left), G2931G (right) on buffstone

Cone 03. Did boiling water, ice water test on both. F crazes (notice the piece is waterlogged). G does not. Buffstone has a high porosity at this temperature so glazes must fit well.

G2931F on F100, Buffstone, L212 and L215

Out of the kiln all fit. However it crazed on buffstone after boiling water, ice water test (use 2931G instead). The others are good. L212 crazes at cone 04.

Firing temperature is important for Zero3 glaze

This is G2931F on Plainsman Buffstone, L213, F100, L215. First column is cone 04, center is cone 03, right is cone 02. All exited the kiln without crazing except Buffstone at cone 04.

We subjected all of them to a 300F:IceWater thermal shock.

Buffstone crazed on all of them.

L215 and L212 Cone 04 crazed.

L213 was good but later the glaze was found to be under excessive compression, subject to shivering over underglazes.

At cone 02 there are some dimples and defects.

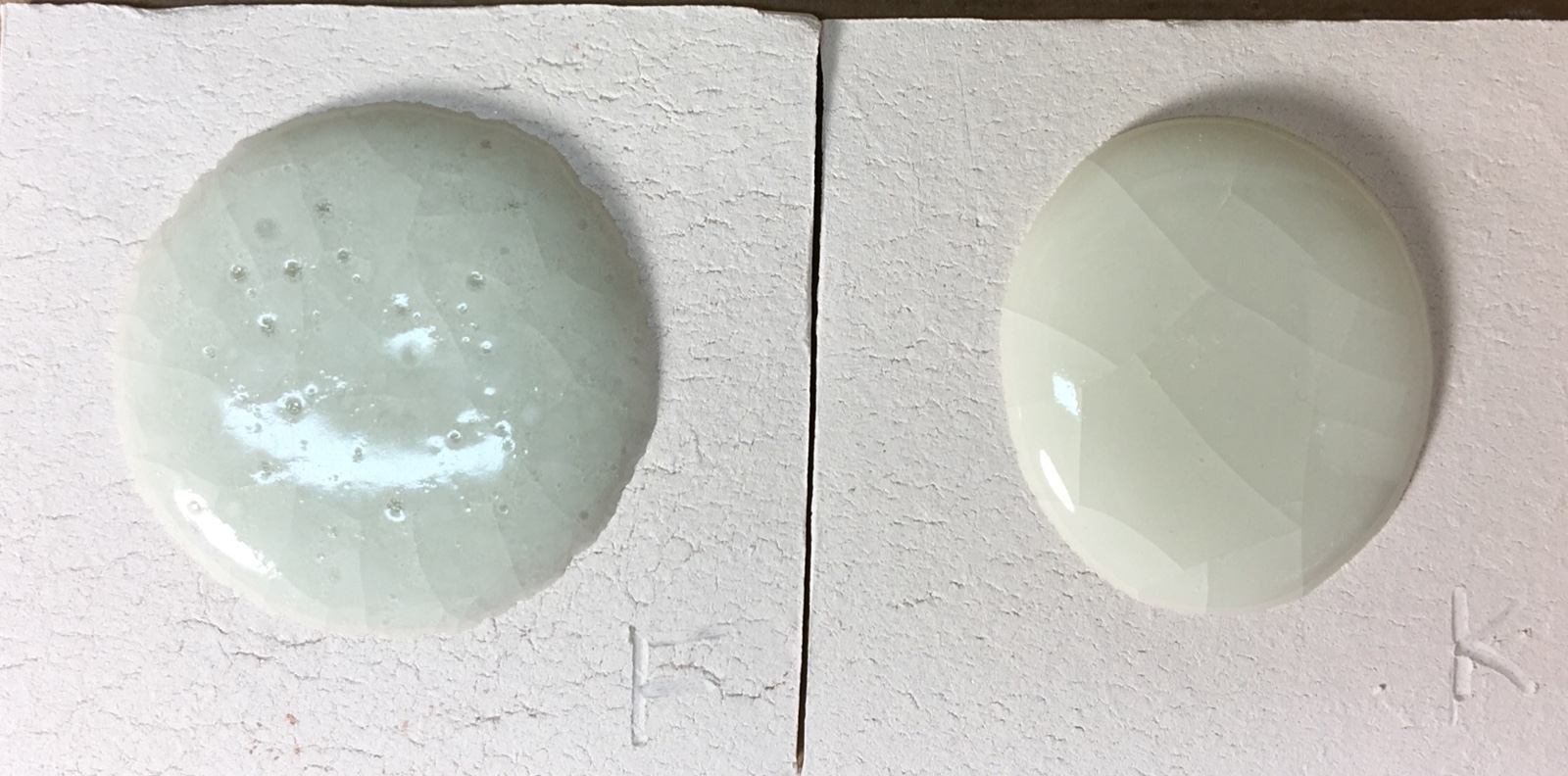

G2931F vs G2931K - Melted balls at cone 03

F, the Ulexite version, is obviously bubbling more, the percolation is causing the melt to spread out more on the tile. On the flow test is was less fluid.

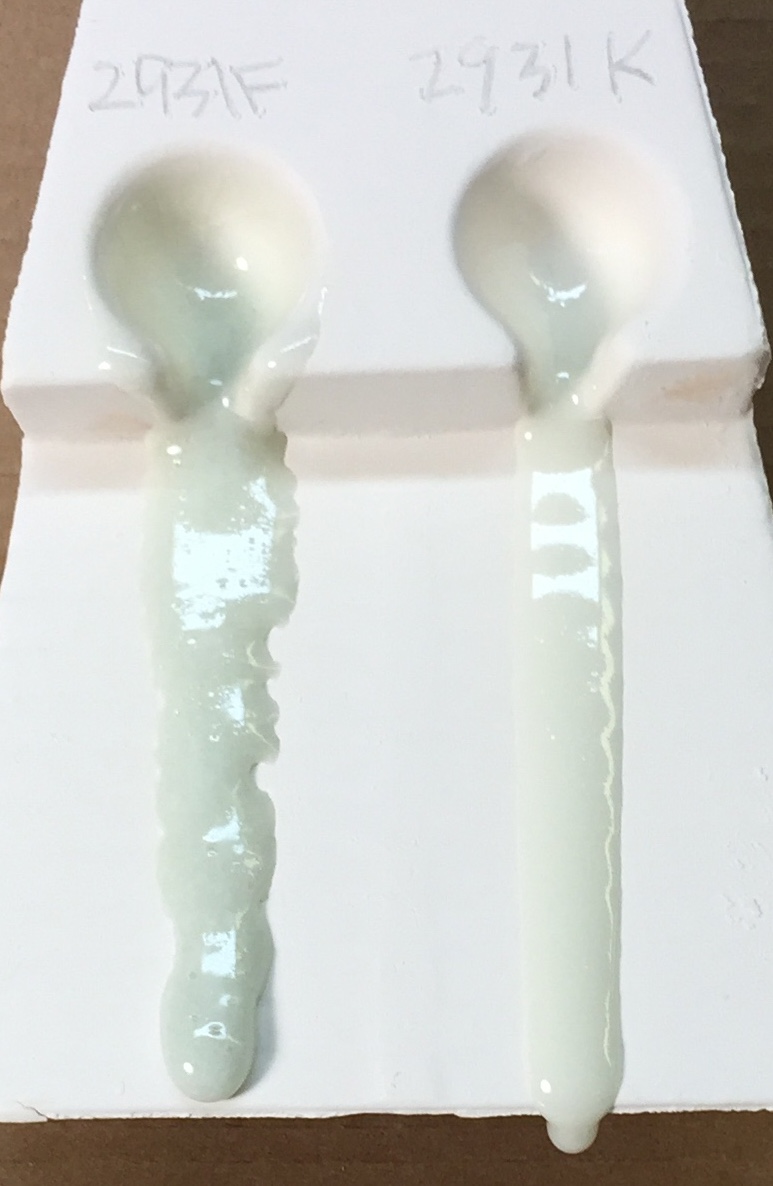

G2931F vs. G2931K on Polar Ice Low Fire

2931F was the Ulexite flused version of this recipe. The F survived three boil:ice cycles and 1 300F:ice cycle without crazing or shivering.

The K is slightly smoother, tiny dimples in the surface are fewer. It is also applied thicker.

G2931F vs 2931K flow test

G2931F on Zero3 Porcelain

The mug was decorated with underglazes at the leather hard stage, then bisque fired to 1650F, then dip-glazed and fired using a cone 03 drop-and-hold firing schedule. This glaze is exceptionally brilliant and clear, it transmits the color of the underglazes better than any other glaze at any other temperature I have seen. This glaze was later upgraded to one having the same chemistry but a higher frit content and firing even better, G2931K.

G2931F on L212, L213 - After one year

No crazing. Even after two years.

A dazzling ultra gloss transparent glaze!

Testdata

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 21.86 | 11.23 | 48.6% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Zero3 Ulexite Transparent Glaze" keywords="For use with the Zero3 body and engobe" id="75426" key="W9oePTd1" date="2022-01-24" codenum="G2931F" picturebasename=""> <recipelines> <recipeline material="EPK" amount="27.000" tolerance=""/> <recipeline material="Silica" amount="7.000" tolerance=""/> <recipeline material="Ulexite" amount="29.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="9.000" tolerance=""/> <recipeline material="Wollastonite" amount="9.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="19.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-19, Modified: 2022-01-24 19:16:09

Zero3 Engobe Recipe

For use with the Zero3 body and glaze

|

Code # L3685U1 |

Location BOX48 |

| Materials | Amt | |

|---|---|---|

| Nepheline Syenite | 10.000 | 9.80% |

| Pioneer Kaolin | 42.000 | 41.18% |

| Ferro Frit 3110 | 25.000 | 24.51% |

| Silica | 20.000 | 19.61% |

| National Standard Bentonite | 5.000 | 4.90% |

Total:102.00

Notes

The Zero3 Engobe finds its inspiration in the ceramic tile industry. Thousands of tons of white engobe are applied to tiles made from red or brown burning bodies, after pressing, to prepare them for glazing. The white surface enables the use of glazes of any color.

This engobe is not required in the Zero3 system, but like tile, it is employed for practical reasons. A typical use case for functional ware is application to inside food surfaces at leather hard state (and covering with the clear transparent Zero3 glaze after bisque firing). Or, as in tile, application to the red-burning body, by dipping or painting, to create a white base onto which coloured underglaze decoration is done. If you are using this engobe on another clay body, especially if not firing to cone 03, do an EBCT test to be sure they are compatible (have the same firing shrinkage), adjust the frit percentage as needed.

This is an engobe, it must be applied at stiff leather-hard stage (if you apply it to dry or bisque it will flake off). It will rewet pieces and they will require significant time to re-stiffen to the same state. Even coverage can normally only be achieved by preparing a slurry of the correct rheological properties and dipping or pouring. It is vital that you have a good mixer and can effectively measure specific gravity. To mix this use the process described on the “Engobe” glossary page at the Digitalfire Reference Library. A paint-on version of this can be made by adding 500g powder engobe to a mix of 400g water and 75g of Laguna Gum Solution (makes 1 pint). This produces brush-stroke coverage, which can be very attractive.

A drop or two of Dettol might be needed to store this for long periods (to prevent bacteria or mold).

Recipe info: The silica helps match body thermal expansion and glaze fit. The frit makes the fired hardness of the engobe more closely match the body. Nepheline Syenite is included as a filler. The bentonite is needed for good adhesion to the leather hard body and for dry hardness.

Pictures

Engobe applied to leather-hard mug

This was done by simply filling and rotate-pouring the engobe, then pressing the lip into it. Since the engobe gels the mug could be turned over immediately without creating any drips.

Notice that the outer surface of the handle has been waxed to slow down its drying. This is because the engobe rewets the mug body, thereby setting it behind the handle. This mug has thin wall so this this rewet adds a day to the production process. This next day the brushwork is done on the outside.

Zero3 body with G2931F Zero3 glaze

The F version of the glaze employs Ulexite to source the boron (instead of frits). These Zero3 stoneware mugs were fired to cone 03 with underglazes. The right mug has the Zero3 engobe inside (under the glaze).

Pulling badly on L212 on EBCT at cone 04

Amaco white engobe vs. L3685U 15% white stain

Even with 15% white stain this engobe is not nearly as white (in the raw state) as the Amaco version. Need to experiment more with whiter kaolins and opacifer additions.

Variations

6100 - Red

1400 powder, 1067 water, 5.6 Darvan produced 1.52 SG. Too runny, took alot of epsom salts. Perhaps water could be reduced. Pulling badly at L212 on EBCT test.

Testdata

EBCT - Engobe Body Compatibility Test

| MATA | MATB | BNDR | BNFR | BCON | |

| 1 | engobe | L212 | 1.6mm | 15mm/engobe | 06 |

| 2 | engobe | L212 | 1.5mm | 10mm | 04 |

| 3 | engobe-brown | L212 | 3.3 | 03 |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Zero3 Engobe Recipe" keywords="For use with the Zero3 body and glaze" id="93335" key="cLSSnXNs" date="2021-02-01" codenum="L3685U1" location="BOX48"> <recipelines> <recipeline material="Nepheline Syenite" amount="10.000" tolerance=""/> <recipeline material="Pioneer Kaolin" amount="42.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="25.000" tolerance=""/> <recipeline material="Silica" amount="20.000" tolerance=""/> <recipeline material="National Standard Bentonite" amount="5.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-11-04, Modified: 2021-02-01 16:04:10

Firing Schedule Name

Cone 03 hold-rise-drop-hold

Degrees (Fahrenheit or Celcius)

F

Schedule Type

Rate

Start Time and Temperature

8:01 am at 80F

Program

| Step | Degrees/Hr | Temperature Monitor |

Hold Time |

Accumulated hrs:min |

Time | Note |

|---|---|---|---|---|---|---|

| 1 | 400 | 240 | 60 | 1:24 | 9:25 am | |

| 2 | 350 | 1850 | 30 | 6:00 | 2:01 pm | |

| 3 | 108 | 1950 | 10 | 6:55 | 2:56 pm | |

| 4 | 500 | 1850 | 30 | 7:07 | 3:08 pm |

Notes

Used to glaze fire Zero3 porcelain and stoneware. However, there is a caution about bisquing these frit-containing bodies: They will vitrify in a typical firing, you must reduce the temperature to around 1500F (if ware is not absorbent enough fire lower). Note: this schedule is for the glaze firing, the previous two sentences simply referenced what is needed for the bisque.

This can start and finish more than once in a working day. Step 2 can often be done as fast as your kiln will go (cold-to-cold in three hours is possible).

The soak at 240F does not fracture ware even though it is above the boiling point of water. We find this is needed to be sure ware is sufficiently dry to withstand the rapid ascent to 1850. If your ware is thicker a slower ascent may be needed.

The 1850 soak on the way up clears the clouds of microbubbles. The 1850 soak on the way down heals the defects (blisters, pinholes) because the increasing viscosity is enough to overcome the surface tension holding bubbles from breaking).

It may be necessary to alter the last step if any imperfections are present. Try dropping to 1800 or 1750 and holding there. An additional step could be added to cool at 100F/hr down to 1500.