Project Name

Engobe for Low Fire Dolomite Body

Project Codenumber

UnAssigned

Notes

The Plainsman Snow clay body (based on the L4410P recipe) fires pure white at low temperatures, making it an ideal base for bright-colored glazes. However, since it contains significant dolomite, it can react with some glazes (e.g. making clear glazes cloudy). In addition, it can be desirable to decorate and color ware at the leather hard or dry stage, bisque, and then dip ware in a transparent glaze. For these reasons, an engobe that works with the body is desirable.

The L3685Z6 was the first trial, it is shown here to give you a better understanding things. It is important to understand the body, glazes and engobe well to be able to use them together. Read the notes carefully. Contact us with questions and we can clarify things as needed.

While we are using a brown stain, the issues here should apply to other colors. It is important to realize that staining an engobe at low temperature requires a higher percentage of pigment (because there is no glass development to intensify the color). Although 15% is needed here, light colors would require much more and this process might not be practical.

Brown Engobe for Snow

|

Code # L3685Z6 |

| Materials | Amt | |

|---|---|---|

| Wollastonite | 20.000 | 19.05% |

| New Zealand Kaolin | 55.000 | 52.38% |

| Silica | 25.000 | 23.81% |

| Ferro Frit 3110 | 5.000 | 4.76% |

| Additions | ||

|---|---|---|

| *6100 Mason Brown Stain | 7.000 | 6.67% |

Total:112.00

Notes

This is version 1 of an engobe to enable customers to color Snow clay (code number L4410P) at the leather hard stage and just finish with transparent on bisque ware.

Based on L3685Z3, this switches Nepheline for Wollastonite to reduce firing shrinkage. This does not appear to have helped, it is 3.5% at cone 04 vs 2.5 for Z3.

To prepare it we mixed the powder with an equal weight of water and then added sodium silicate to thin it to a good working consistency. It took repeated additions, the slurry kept re-thickening on use. It also took alot of mixing energy to break up the NZK agglomerates. Since this is being stained anyway that white NZ Kaolin is not really needed, other kaolins are much easier to mix in (although they will need help from bentonite to be sticky enough).

This is not firing dark enough, either the wrong stain, wrong glaze not high enough percentage of stain.

This needs bentonite, it is not plastic enough and does not have enough dry hardness. However it does apply well the the leather hard ware.

Bi-Clay bars are curling toward this engobe, but only about 4mm.

Pictures

L3685Z5 engobe on Plainsman Snow clay at cone 04

Glaze is G1916Q3.

L3685Z6 on snow with G1916Q3 glaze - Closeup

It is difficult to tell if the cloudiness is bubbles or crystals.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | CONE | DSHR | FSHR | ABS | |

| 1 | 96.67 | 93.59 | -4.0 | 3.3% | 3.2% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Brown Engobe for Snow" id="213699" key="x9TmmovT" date="2022-03-18" codenum="L3685Z6"> <recipelines> <recipeline material="Wollastonite" amount="20.000" tolerance=""/> <recipeline material="New Zealand Kaolin" amount="55.000" tolerance=""/> <recipeline material="Silica" amount="25.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="5.000" tolerance=""/> <recipeline material="6100 Mason Brown Stain" amount="7.000" added="true"/> </recipelines> </recipe> </recipes>

Born: 2021-03-08, Modified: 2022-03-18 13:38:57

Cone 04 Brown Engobe for Snow

|

Code # L3685Z7 |

Location BOX 54 |

| Materials | Amt |

|---|---|

| Nepheline Syenite | 23.000 |

| Tile #6 Kaolin | 47.000 |

| Silica | 20.000 |

| Ferro Frit 3110 | 5.000 |

| Additions | |

|---|---|

| National Standard Bentonite | 3.000 |

| *Mason 6100 Stain | 15.000 |

Total:113.00

Notes

Based on L3685Z6, addressing a number of issues. This is the best engobe so far for using on Plainsman Snow at cone 04 (40% dolomite, 10% Nepheline, 50% ball clay).

-Uses 6Tile for easier mixing and more plasticity.

-Nepheline instead of wollastonite (or the previous Minspar) for convenience in Canada. The wollastonite did not reduce firing shrinkage as expected either.

-Added bentonite to increase firing shrinkage to better match the snow (and make it stickier).

Like the Z6, we added the powder to an equal weight of water and propeller mixed really well. This did not require as much bentonite. The creamy consistency achieved after addition of sodium silicate (just a few drops in a gallon) produced a slurry that applied very evenly and gelled in place without dripping. It worked very well.

Even though Plainsman Snow has zero firing shrinkage, it appears from testing here (see below) that it can tolerate an engobe that has 3% firing shrinkage.

The fired shrinkage of this engobe is higher than Snow. But it is only 3%. The BiClay bars are certainly curved, but the thickness of engobe half is 2mm. Time will tell if the fit is OK. The frit could be removed for a reduction to maybe to 2% firing instead shrinkage at cone 04, but surface hardness and body bonding enabled by it would be lost.

This fires to a harder surface than the Snow clay, so it is a benefit.

Pictures

Four cone 04 clear glazes cover L3685Z7 engobe differently

These are Plainsman Snow (the L4410P recipe) cast pieces with L3685Z7 stained engobe on the upper sections. The four sides have been clear glazed with Mayco S-2101, Duncan PB001, Amaco LG-10 and Spectrum 700 transparent glazes. The left half of each has an extra glaze layer, that has not made much difference in any of them. The S-2101 transmits the brown color best, the LG-10 and PB001 a little less. The 700 is decidedly lighter, it is altering the brown color (likely MgO in the glaze is reacting with the stain). However, over the white body, the 700 is by far the best, being crystal clear and glassy smooth. The lower halves of these also demonstrate something equally interesting: The ones that don't alter the brown do react with the MgO in the white body, yellowing it and turning opaque. The lesson is to try various brands of clear glazes over underglaze decoration and colored engobes, especially with dolomite-based low fire bodies. It might even be advantageous to use one brand on the insides of pieces and another on the engobe or slip-decorated exteriors.

L3685Z7 engobe vs Plainsman Snow BiClay bars

BiClay strips with Snow dried flat but curled 13mm toward Z7 at cone 05 and 15mm toward Z7 at cone 04.

It is amazing that, although the body has no glass development, it is able to bend this much on firing without cracking or breaking.

The bars dried perfectly straight so the drying compatibility is good.

L3685Z7 Snow interface

I dropped the BiClay bars onto cement and they were very strong, they did not shatter (indicating no residual stresses within). The bars broke at right angles except when struck with a hammer. Even when breaking on an angle, the join never failed in preference to any other plane.

Snow with L3685Z7 engobe at Spectrum 700 clear

When thin the glaze is not reacting as much with the engobe. It appear the engobe is creating cloudiness in the glaze, perhaps micro-crystals or micro-bubbles.

L3685Z7 fired bars

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 2 | 94.1 | 89.48 | 40.27 | 44.18 | -3.0 | 5.9% | 4.9% | 9.7% |

| 1 | 94.15 | 91.02 | 37.9 | 42.93 | -4.0 | 5.8% | 3.3% | 13.3% |

| 3 | 94.43 | 92.44 | 39.89 | 45.81 | -5.0 | 5.6% | 2.1% | 14.8% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 04 Brown Engobe for Snow" id="213989" key="KqubgPJQ" date="2022-08-25" codenum="L3685Z7" location="BOX 54"> <recipelines> <recipeline material="Nepheline Syenite" amount="23.000" tolerance=""/> <recipeline material="Tile #6 Kaolin" amount="47.000" tolerance=""/> <recipeline material="Silica" amount="20.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="5.000" tolerance=""/> <recipeline material="National Standard Bentonite" amount="3.000" added="true"/> <recipeline material="Mason 6100 Stain" amount="15.000" added="true"/> </recipelines> </recipe> </recipes>

Born: 2014-11-04, Modified: 2022-08-25 08:55:42

L213 40:10 Dolo/NS

|

Code # L4410P |

| Materials | Amt | Units |

|---|---|---|

| KT #1-4 Ball Clay | 50.000 | GM |

| Dolocron 413 (Dolomite) | 40.000 | GM |

| Nepheline Syenite | 10.000 | GM |

Total:100.00 (R)

Notes

This is a low temperature, white firing body to replace tranditional talc:ball clay bodies. We have done many previous tests that indicate that 40% dolomite is needed. That being said, glazes have been fitting well enough we are testing 35%.

So far, Duncan, Spectrum and Mayco transparent glazes are not crazing! The Mayco and Duncan glazes need to be put on thicker (they almost seem to be absorbing into the body), the Spectrum one works normally. The Mayco and Duncan have a higher thermal expansion, so they will craze sooner, in fact the Duncan PB001 crazes when thick on L213 (50:50 ball clay:talc). That gives confidence that the Spectrum 700 glaze should endure without crazing. The use of the G3879C base clear on this will produce glaze compression cracking.

One down side of this body is a much higher porosity. Strangely this does not seem to affect the strength of glazed fired ware. An interesting side effect of that is that this readily absorbs a sealer to make it water tight. This density of the fired ceramic is 1.44 (vs. 2.2 for a vitreous porcelain).

This has the potential of being valuable for decorative tile (since it has almost zero firing shrinkage the tiles will fire flat). The fired strength is excellent, even after just a bisque firing.

Some users have reported splitting of ware during firing. We are suspicious that the dolomite is rehydrating for people who store bisque in damp conditions or where glazes do not dry immediately. Thus, glaze and fire your ware soon after bisque (or store bisque in plastic bags in damp conditions) and force dry glazes if needed.

Pictures

L4410P - Mayco S2101, Duncan PB001, Spectrum 700

Fired cone 05. No crazing after weeks on any of them. The 700 glaze fires much whiter than the Duncan or Mayco on this body (it must be using a higher quality frit).

Spectrum 700 on L4410M, N, P, Q - Cone 05

No crazing out of the kiln on any of them (these of some of the many recipe tests we did before settling on the P version). This is a testament to how good of a glaze the Spectrum 700 is. It fires more transparent (therefore whiter) than the others and fits better.

L4410 after several days soaking in water

The water as wicked up the walls (between the glazed inner and outer surfaces). After several days there is no crazing with Spectrum 700 or L3879C.

L4410P at cone 05 with Spectrum coloured glazes

These are slip-cast pieces.

We are getting very good results with all glazes tried.

Spectrum 753 Bright Yellow, 746 Bright Purple, 706 Royal Blue, 743 Bright Red

Inside: #700

Firing schedule was BTSG05, bisque was BTFB04.

This body is trickier to deflocculate than the talc version, we are working on a procedure using Darvan and Sodium Silicate.

L4410P at cone 06 (back), cone 6 (front)

Engobe is AMACO velvet. This clay sags and warps at cone 6 yet does not bloat and still has good fired strength. These pieces are slip cast.

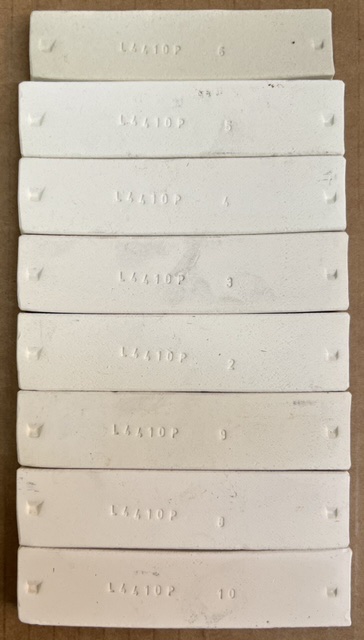

L4410P fired bars

From cone 6 and 5 (top) down to cone 06.

L4410P sealed and unsealed

The body has high porosity, but this has an advantage: It soaks up silicone sealer very well. The slip-cast piece on the left was sealed (you can see the surface sheen) and it is impermeable to water penetration (the glaze is not crazed so water cannot penetrate there either). The piece on the right soaks up water readily (on the lower unglazed portion).

The porosity of the body has another advantage: It does not appear to be subject to moisture expansion (which would craze the glaze).

Bonding test of Spectrum 700 on L4410P

This GBBT test indicates a very good glaze-body interface.

L4494 fired bars

This is L4410P with 4% iron oxide added. Bars are fired from cone 5 (top) down to cone 06 (bottom).

Clearly, the dolomite is muting the color.

G3879C on L4410P dolomite body at cone 04

The outside glaze is Spectrum 336. The G3879C is our recipe, a base transparent that we have been tuning to reduce the thermal expansion as much as possible to fit our 50:40:10 BallClay:Dolomite:Nepheline body. The result is glaze compression, it is now under enough compression on the inside of this piece that it is forcing it apart.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 6 | 94.6 | 88.04 | 33.01 | 36.92 | 6.0 | 5.4% | 6.9% | 11.8% |

| 5 | 94.6 | 94.23 | 33.19 | 42.43 | 5.0 | 5.4% | 0.4% | 27.8% |

| 4 | 94.12 | 94.7 | 33.01 | 41.89 | 4.0 | 5.9% | -0.6% | 26.9% |

| 3 | 94.31 | 95.15 | 33.6 | 43.38 | 3.0 | 5.7% | -0.9% | 29.1% |

| 2 | 94.59 | 95.57 | 33.47 | 42.97 | 2.3 | 5.4% | -1.0% | 28.4% |

| 1 | 94.59 | 95.54 | 32.11 | 41.35 | 1.0 | 5.4% | -1.0% | 28.8% |

| 7 | 94.23 | 5.8% | ||||||

| 12 | 94.57 | 5.4% | ||||||

| 9 | 94.46 | 95.17 | 33.52 | 42.92 | -2.0 | 5.5% | -0.8% | 28.0% |

| 8 | 94.6 | 94.91 | 33.34 | 43.11 | -5.0 | 5.4% | -0.3% | 29.3% |

| 10 | 94.69 | 94.85 | 34.22 | 43.88 | -6.0 | 5.3% | -0.2% | 28.2% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 12.43 | 10.25 | 7.82 | 17.5% | 23.7% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="L213 40:10 Dolo/NS" id="208137" key="ckPBk1QN" date="2024-11-19" codenum="L4410P"> <recipelines> <recipeline material="KT #1-4 Ball Clay" amount="50.000" tolerance="" unitabbr="GM"/> <recipeline material="Dolocron 413" lookup="Dolomite" amount="40.000" tolerance="" unitabbr="GM"/> <recipeline material="Nepheline Syenite" amount="10.000" tolerance="" unitabbr="GM"/> </recipelines> </recipe> </recipes>

Born: 2021-10-28, Modified: 2024-11-19 02:08:24