Project Name

Replace talc in low temperature white body

Project Codenumber

UnAssigned

Notes

Talc has always been the "accepted" way of making low-fire white bodies. Mixtures of ball clay and talc produce outstanding working, casting, drying and firing properties. Talc is the secret behind raising the thermal expansion to fit commercial cone 06-02 glazes. And this mix creates fantastic plastic working properties (and casting). Until now, in North America, talc and ball clay grades could be selected to produce a very white burning body. Although the traditional talc mix is porous and has poor strength in the fired state, these factors are discounted in order to provide hobbyists and artware producers a white "canvas" on which to apply colorful glazes! That means the dark-burning talcs are "non-starters".

However, a major problem arose during 2021: Texas talc ceased production. North American industry initially looked toward other talcs, but they fire significantly darker or are also ceasing production. A climate of litigation seems to be the reason for the demise of this material. A Chinese talc is available, but unlike the Texas talcs, it is not asbestos-free. Fortunately, it is possible to make a body that fires just as white and strong with zero-talc.

We did a series of tests blending Nepheline Syenite, silica and Dolomite to substitute for the 50% talc in our main recipe, L213. It turned out a 80:20 Nepheline:Dolomite mix produces a white-burning body that fits typical glazes. These materials are easily available to us (nepheline syenite is a Canadian material, if you are in the US consider using a white feldspar).

An interesting finding in our testing has been that popular transparent glazes are not transparent, they fire amber and significantly darken the color of the white body. Spectrum Glazes #700 Clear is by far the best glaze we have tested (out of 5 brands).

The base transparent recipes (shown here) are a good option if you can mix your own. Stains and opacifiers can be added to these to make any color or effect. For now, consider substituting one of these as your transparent, and continue to use all the commercial colored glazes (and tolerate possible crazing with them). Another factor: Worldwide supply chain issues could affect the availability of glazes you use, so knowing how to mix your own from scratch and adjust it to be a brushing glaze, dipping glaze or base coat, is not a bad thing! The proportions of water:powder that we use are shown. Go to https://digitalfire.com/article/98 for more information on getting started mixing your own.

Feb 2023: It has been at least a year using and selling the dolomite body, we are still using 40% (although experimenting with 35%). Customers are learning and enjoying its benefits more and more. Some others are switching back to talc bodies that have again become available from other manufacturers.

If you are in production, you might want to consider using a terra cotta, for example, our G4170B (plastic and casting versions both work very well). For a white surface use the matching engobe, L3685Z2. See the link above for more information. Terra cotta bodies fire to much better strength and glaze fit is much less of an issue. Terra cotta bodies are also less expensive and have excellent workability. And, by firing to cone 03-02 stoneware strength can be achieved.

Pictures

L213 NS:Dolo 30:20

|

Code # L4410L |

| Materials | Amt | Units |

|---|---|---|

| KT #1-4 Ball Clay | 50.000 | GM |

| Nepheline Syenite | 30.000 | GM |

| Dolocron 4013 (Dolomite) | 20.000 | GM |

| Additions | Units | |

|---|---|---|

| Bentonite | 3.000 | GM |

Total:103.00 (R)

Notes

L213 is a body made by Plainsman Clays, it has traditionally employed Texas talc and KT1-4 ball clay, a simple 50:50 mix. This is part of a project to explore the possibility that a Nepheline Syenite/Dolomite blend could replace it.

This is the casting version of the body. If pieces are unable to pull away from the mold without cracking, add a tiny amount of bentonite to improve plastic strength (e.g. 0.5%). For use on a potters wheel at about 3% bentonite.

Talc is is a magnesia mineral and so is dolomite. Can a small amount of dolomite encourage the growth of cristobalite and increase the thermal expansion of a body the same way that talc does? This recipe appears to say yes! Initial glaze testing of this looked promising. Fired whiteness is amazing. We are stunned by the quality of pieces we have been able to produce with this using standard low fire Spectrum glazes. However, over time it became clear that crazing will eventually occur.

Plasticity and workability is also as good or better than the former talc body.

A real plus is that this body employs Nepheline Syenite as a filler, instead of quartz. That makes it even safer to use.

Our G3879C and G1916QL1 glaze recipes are working well on this.

A test run of the plastic version of this was made at Plainsman Clays August 2021.

Unless otherwise noted we generally use our C04PLTP firing schedule.

Dry strength appears to be lower than for a ball clay:talc mix.

Pictures

Spectrum 700 clear and 742 red on L4410L

Out-of-the kiln there is no crazing, results are stunning! However over a few weeks the glazes did craze.

K4410K (left), L4410L (right) - Cone 6

This body has another advantage over the talc version: Although it begins to warp at cone 6 (stoneware temperature), it is not brittle, fired strength is excellent. That means that it should survive to cone 4. Another things that the is remains porous if bisque fired to cone 02 or even 2. This

L4410K cone 03 with spectrum brush-on glazes

L4410K had a 35:15 nepheline:dolomite mix (to substitute for the 50 talc).

Spectrum 742 dark red, 705 black, 700 clear.

Out of the kiln there was no crazing but over a few weeks they did.

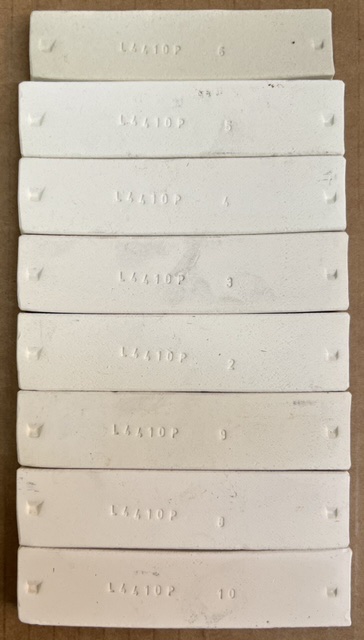

P6936 L213 test with original lab mix - test bars

Bars are fired from cone 6 (top right) down to cone 04 (bottom right).

L4410L with G1916Q, G1916QL and G3879 - Cone 04

Only the G1916Q is crazing after several months.

The L4410L body is 50:30:20 Ball clay, Nepheline, Dolomite.

G3879C, G1916QL1 on L4410L Bisque 1800 glaze cone 04

No crazing after weeks of use, ultragloss.

Frit 524 has much less iron, that is why that mug is so much whiter.

After several months at home the G3879C did craze.

Duncan, Mayco matte glazes on L4410L at cone 04

No crazing out of kiln but both crazed about a week later.

Duncan PB001 on L4410L cone 04 bisque 06 glaze - crazing

Duncan, Mayco glossy glazes on L4410L at cone 04

Crazing out of kiln, both.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 6 | 93.42 | 91.14 | 35.41 | 35.51 | 6.0 | 6.6% | 2.4% | 0.3% |

| 7 | 93.38 | 93.21 | 35.81 | 42.71 | 6.0 | 6.6% | 0.2% | 19.3% |

| 5 | 93.18 | 92.76 | 35.51 | 40.3 | 5.0 | 6.8% | 0.5% | 13.5% |

| 4 | 93.01 | 92.51 | 35.89 | 41.72 | 4.0 | 7.0% | 0.5% | 16.2% |

| 3 | 93.38 | 92.95 | 35.78 | 42.23 | 3.0 | 6.6% | 0.5% | 18.0% |

| 2 | 93.67 | 93.32 | 35.87 | 42.23 | 2.0 | 6.3% | 0.4% | 17.7% |

| 1 | 93.77 | 93.46 | 34.01 | 40.5 | 1.0 | 6.2% | 0.3% | 19.1% |

| 10 | 93.83 | 93.54 | 34.93 | 41.36 | -.8 | 6.2% | 0.3% | 18.4% |

| 9 | 93.61 | 93.37 | 35.43 | 42.01 | -1.8 | 6.4% | 0.3% | 18.6% |

| 8 | 93.44 | 93.1 | 35.27 | 42.02 | -4.0 | 6.6% | 0.4% | 19.1% |

SOLU - Soluble Salts

| FIRE | |

| 1 | nil |

DFAC - Drying Factor

| DFAC | SOLD | |

| 1 | A000 | vlight |

CLWC - Clay Water Content - Powder, Plastic

| PUGW | PUGD | POW% | PUG% | |

| 1 | 25.74 | 20.48 | 20.4% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 13.03 | 10.56 | 8.97 | 19.0% | 15.1% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="L213 NS:Dolo 30:20" id="201792" key="wkejK3Wu" date="2024-11-19" codenum="L4410L"> <recipelines> <recipeline material="KT #1-4 Ball Clay" amount="50.000" tolerance="" unitabbr="GM"/> <recipeline material="Nepheline Syenite" amount="30.000" tolerance="" unitabbr="GM"/> <recipeline material="Dolocron 4013" lookup="Dolomite" amount="20.000" tolerance="" unitabbr="GM"/> <recipeline material="Bentonite" amount="3.000" unitabbr="GM" added="true"/> </recipelines> </recipe> </recipes>

Born: 2021-02-06, Modified: 2024-11-19 02:08:57

L213 40:10 Dolo/NS

|

Code # L4410P |

| Materials | Amt | Units |

|---|---|---|

| KT #1-4 Ball Clay | 50.000 | GM |

| Dolocron 413 (Dolomite) | 40.000 | GM |

| Nepheline Syenite | 10.000 | GM |

Total:100.00 (R)

Notes

This is a low temperature, white firing body to replace tranditional talc:ball clay bodies. We have done many previous tests that indicate that 40% dolomite is needed. That being said, glazes have been fitting well enough we are testing 35%.

So far, Duncan, Spectrum and Mayco transparent glazes are not crazing! The Mayco and Duncan glazes need to be put on thicker (they almost seem to be absorbing into the body), the Spectrum one works normally. The Mayco and Duncan have a higher thermal expansion, so they will craze sooner, in fact the Duncan PB001 crazes when thick on L213 (50:50 ball clay:talc). That gives confidence that the Spectrum 700 glaze should endure without crazing. The use of the G3879C base clear on this will produce glaze compression cracking.

One down side of this body is a much higher porosity. Strangely this does not seem to affect the strength of glazed fired ware. An interesting side effect of that is that this readily absorbs a sealer to make it water tight. This density of the fired ceramic is 1.44 (vs. 2.2 for a vitreous porcelain).

This has the potential of being valuable for decorative tile (since it has almost zero firing shrinkage the tiles will fire flat). The fired strength is excellent, even after just a bisque firing.

Some users have reported splitting of ware during firing. We are suspicious that the dolomite is rehydrating for people who store bisque in damp conditions or where glazes do not dry immediately. Thus, glaze and fire your ware soon after bisque (or store bisque in plastic bags in damp conditions) and force dry glazes if needed.

Pictures

L4410P - Mayco S2101, Duncan PB001, Spectrum 700

Fired cone 05. No crazing after weeks on any of them. The 700 glaze fires much whiter than the Duncan or Mayco on this body (it must be using a higher quality frit).

Spectrum 700 on L4410M, N, P, Q - Cone 05

No crazing out of the kiln on any of them (these of some of the many recipe tests we did before settling on the P version). This is a testament to how good of a glaze the Spectrum 700 is. It fires more transparent (therefore whiter) than the others and fits better.

L4410 after several days soaking in water

The water as wicked up the walls (between the glazed inner and outer surfaces). After several days there is no crazing with Spectrum 700 or L3879C.

L4410P at cone 05 with Spectrum coloured glazes

These are slip-cast pieces.

We are getting very good results with all glazes tried.

Spectrum 753 Bright Yellow, 746 Bright Purple, 706 Royal Blue, 743 Bright Red

Inside: #700

Firing schedule was BTSG05, bisque was BTFB04.

This body is trickier to deflocculate than the talc version, we are working on a procedure using Darvan and Sodium Silicate.

L4410P at cone 06 (back), cone 6 (front)

Engobe is AMACO velvet. This clay sags and warps at cone 6 yet does not bloat and still has good fired strength. These pieces are slip cast.

L4410P fired bars

From cone 6 and 5 (top) down to cone 06.

L4410P sealed and unsealed

The body has high porosity, but this has an advantage: It soaks up silicone sealer very well. The slip-cast piece on the left was sealed (you can see the surface sheen) and it is impermeable to water penetration (the glaze is not crazed so water cannot penetrate there either). The piece on the right soaks up water readily (on the lower unglazed portion).

The porosity of the body has another advantage: It does not appear to be subject to moisture expansion (which would craze the glaze).

Bonding test of Spectrum 700 on L4410P

This GBBT test indicates a very good glaze-body interface.

L4494 fired bars

This is L4410P with 4% iron oxide added. Bars are fired from cone 5 (top) down to cone 06 (bottom).

Clearly, the dolomite is muting the color.

G3879C on L4410P dolomite body at cone 04

The outside glaze is Spectrum 336. The G3879C is our recipe, a base transparent that we have been tuning to reduce the thermal expansion as much as possible to fit our 50:40:10 BallClay:Dolomite:Nepheline body. The result is glaze compression, it is now under enough compression on the inside of this piece that it is forcing it apart.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 6 | 94.6 | 88.04 | 33.01 | 36.92 | 6.0 | 5.4% | 6.9% | 11.8% |

| 5 | 94.6 | 94.23 | 33.19 | 42.43 | 5.0 | 5.4% | 0.4% | 27.8% |

| 4 | 94.12 | 94.7 | 33.01 | 41.89 | 4.0 | 5.9% | -0.6% | 26.9% |

| 3 | 94.31 | 95.15 | 33.6 | 43.38 | 3.0 | 5.7% | -0.9% | 29.1% |

| 2 | 94.59 | 95.57 | 33.47 | 42.97 | 2.3 | 5.4% | -1.0% | 28.4% |

| 1 | 94.59 | 95.54 | 32.11 | 41.35 | 1.0 | 5.4% | -1.0% | 28.8% |

| 7 | 94.23 | 5.8% | ||||||

| 12 | 94.57 | 5.4% | ||||||

| 9 | 94.46 | 95.17 | 33.52 | 42.92 | -2.0 | 5.5% | -0.8% | 28.0% |

| 8 | 94.6 | 94.91 | 33.34 | 43.11 | -5.0 | 5.4% | -0.3% | 29.3% |

| 10 | 94.69 | 94.85 | 34.22 | 43.88 | -6.0 | 5.3% | -0.2% | 28.2% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 12.43 | 10.25 | 7.82 | 17.5% | 23.7% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="L213 40:10 Dolo/NS" id="208137" key="zs2Q4BkR" date="2024-11-19" codenum="L4410P"> <recipelines> <recipeline material="KT #1-4 Ball Clay" amount="50.000" tolerance="" unitabbr="GM"/> <recipeline material="Dolocron 413" lookup="Dolomite" amount="40.000" tolerance="" unitabbr="GM"/> <recipeline material="Nepheline Syenite" amount="10.000" tolerance="" unitabbr="GM"/> </recipelines> </recipe> </recipes>

Born: 2021-10-28, Modified: 2024-11-19 02:08:24

Cone 05+ Lower Expansion glaze

|

Code # G1916QL1 |

| Materials | Amt |

|---|---|

| Ferro Frit 3195 | 60.000 |

| Ferro Frit 3249 | 25.000 |

| New Zealand or Grolleg kaolin (Grolleg Kaolin) | 10.000 |

| 45 micron Silica (Silica) | 5.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.9:1 6.0 (Molar:6.0) 1.2 |

Notes

This is a much-lower-thermal-expansion version of our standard G1916Q low fire clear recipe (which was delay-crazing on the L4410C, L4410K, L4410L cone 04 test bodies). The lower expansion was achieved by eliminating all high-expansion 3110 and more than doubling the low-expansion 3249. This now shivers on our L4170B terra cotta (use the G1916Q for it).

This also switches the ball clay for New Zealand or Grolleg kaolin, removed the amber coloration from the glass. And this is melting better (since frit 3249 is a very active flux), that means it is very practical at cone 05.

The lower surface tension of this also makes it a better candidate than G3879 for opacification with zircon.

We did initial mixes using both Grolleg and New Zealand kaolins. The slurry rheologies were the same. Sieving to at least 80 mesh or blender mixing is required to break down these kaolins (they are very sticky and form agglomerates).

The initial mixes for a dipping glaze were 1500g powder, 1200g water producing a specific gravity of 1.49 and yielding just over 1.80 litres.

The down side of this recipe is settling (after a few weeks). And it is going on too thick on bisque, even on a quick dip. Leaving the recipe as is at least some CMC gum is needed for water retention Increasing the water to 50% (thus a 1:1 mix of water:powder) and adding 0.5% Veegum improved the slurry without causing and dripping or excessively slow drying. That being said, it is still settling more than desired. If the cleanest possible transparent is not the priority the G1916QL recipe is easier to get a good slurry.

Conversely, this recipe is working well for brushing glazes. We make 1 pint using 340g powder, 440g water, 5g CMC gum and 5g of Veegum. On aging we add more CMC if needed (by blender mixing). Even when it dries out to 50:50 water:powder it still paints well.

Pictures

G3879C, G1916Q, G1916QL1 on L213 Cone 04

The move from ball clay to New Zealand kaolin (centre mug vs right mug) greatly improves the clarity (because of the reduction in iron and titanium).

Cone 04 G1916QL1 vs G3879C melt flow comparison

G1916QL1 is more melt fluid so it is likely useful before cone 04. But G3879C is also very fluid (it also has a higher surface tension). Both are producing textbook high quality flows.

Spectrum 705 Black, G1916QL clear on L4410K at cone 03

The quality of this piece is amazing! The evenness of coverage that can be achieved with brush-on glazes is impressive. This was my favourite coffee mug. However it did finally craze after about 2 weeks of use (that motivated the recipe change to G1916QL1).

G3879C, G1916QL1 on L4410L Bisque 1800 glaze cone 04

No crazing after weeks of use, ultragloss.

Frit 524 has much less iron, that is why that mug is so much whiter.

After several months at home the G3879C did craze.

G1916QL1. G3879C, G3879G1 on L213 tiles - Cone 04

These are all craze-free after several months.

G1916QL1 on medium temperature porcelains

Clockwise from top left: L213, M370, P300, Polar Ice

After a month none of these have crazed. After several months the P300 crazed.

At cone 03 the glaze is more transparent and brilliant than with anything possible at cone 6.

At cone 04 and 05 the porcelains eventually do craze.

Cost comparison vs. Spectrum 700 Clear

G1916QL1 on L215 - more than a year old

This was done as a brushing version of this recipe.

Not crazing, not shivering.

Refired a year later, clouding reduced slightly.

Testdata

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 16.55 | 9.52 | 42.5% | ||

| 2 | 11.67 | 5.94 | 49.1% | ||

| 3 | 5.04 | 2.43 | 51.8% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 05+ Lower Expansion glaze" id="202545" key="T2kWHniu" date="2024-03-29" codenum="G1916QL1"> <recipelines> <recipeline material="Ferro Frit 3195" amount="60.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="25.000" tolerance=""/> <recipeline material="New Zealand or Grolleg kaolin" lookup="Grolleg Kaolin" amount="10.000" tolerance=""/> <recipeline material="45 micron Silica" lookup="Silica" amount="5.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-04, Modified: 2024-03-29 18:06:15

Cone 04 UltraClear Low-Expansion

|

Code # G3879C |

| Materials | Amt | |

|---|---|---|

| Fusion Frit F-524 | 750.000 | 73.17% |

| Fusion Frit F-69 | 140.000 | 13.66% |

| New Zealand or Grolleg kaolin (Grolleg Kaolin) | 90.000 | 8.78% |

| Silica 45 micron (Silica) | 45.000 | 4.39% |

Total:1,025.00

Auto Unity Formula

|

Si:Al: 8.0:1 6.2 (Molar:5.8) 1.1 Cost 2.73 per kg |

Notes

An adjusted version of G3879 to reduce thermal expansion. It switches the silica to 45 micron (325 mesh) for better dissolution in the melt. And it increases the frit low-expansion F-69 (the Fusion equivalent of Ferro 3249) at the expense of F-524.

This also switches to whiter burning kaolin (New Zealand), that improves transparency and removes the amber coloration.

It still fires to the same crystal clear on light burning bodies (but clouding on terra cottas unless applied thinly). And is fitting pieces better.

For a dipping glaze we mix 1500g powder to 1125g water (57%/43%) to get a specific gravity of 1.54. This produces 1.7 litres. This builds up thickness quickly on Snow clay (because it is so absorbent).

For a brushing version we mix 350g powder with 5g Veegum and 5g CMC gum, shake this an add it to 450 water and then mix in a kitchen blender. This produces a gelled slurry that paints well.

Pictures

G3879C is firing much whiter, why?

Cone 04. All three clear glazes are on the same body. Left to right: Amaco LG10, G3879C recipe, Crysanthos SG213. The middle one employs Fusion Frit F-524, it is more expensive. But look at the benefit: It fires much more transparent so the piece is much whiter. And it is not crazing or pin holing. And it is glossier.

G3879C, G1916Q, G1916QL1 on L213 Cone 04

The move from ball clay to New Zealand kaolin (centre mug vs right mug) greatly improves the clarity (because of the reduction in iron and titanium).

G3879C vs. G1916QL on L4410K low fire white

The iron from the ball clay is the reason the glaze on the right is off-white.

Cone 04 G1916QL1 vs G3879C melt flow comparison

G1916QL1 is more melt fluid so it is likely useful before cone 04. But G3879C is also very fluid (it also has a higher surface tension). Both are producing textbook high quality flows.

G3879C, G1916QL1 on L4410L Bisque 1800 glaze cone 04

No crazing after weeks of use, ultragloss.

Frit 524 has much less iron, that is why that mug is so much whiter.

After several months at home the G3879C did craze.

G1916QL1. G3879C, G3879G1 on L213 tiles - Cone 04

These are all craze-free after several months.

G3879C on L4410P dolomite body at cone 04

The outside glaze is Spectrum 336. The G3879C is our recipe, a base transparent that we have been tuning to reduce the thermal expansion as much as possible to fit our 50:40:10 BallClay:Dolomite:Nepheline body. The result is glaze compression, it is now under enough compression on the inside of this piece that it is forcing it apart.

G3879C on L215, Buffstone at cone 02

Clouding badly on terra cotta, better on the white body.

G3879C on L4170B at cone 04 with L3685Z6 engobe

No crazing after six months or more.

An even but not too thick application was achieved by dipping, not brushing.

Testdata

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 11.4 | 6.43 | 43.6% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 04 UltraClear Low-Expansion" id="202474" key="eXqFNPkv" date="2022-12-19" codenum="G3879C"> <recipelines> <recipeline material="Fusion Frit F-524" amount="750.000" tolerance=""/> <recipeline material="Fusion Frit F-69" amount="140.000" tolerance=""/> <recipeline material="New Zealand or Grolleg kaolin" lookup="Grolleg Kaolin" amount="90.000" tolerance=""/> <recipeline material="Silica 45 micron" lookup="Silica" amount="45.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2019-04-15, Modified: 2022-12-19 22:22:22